[ad_1]

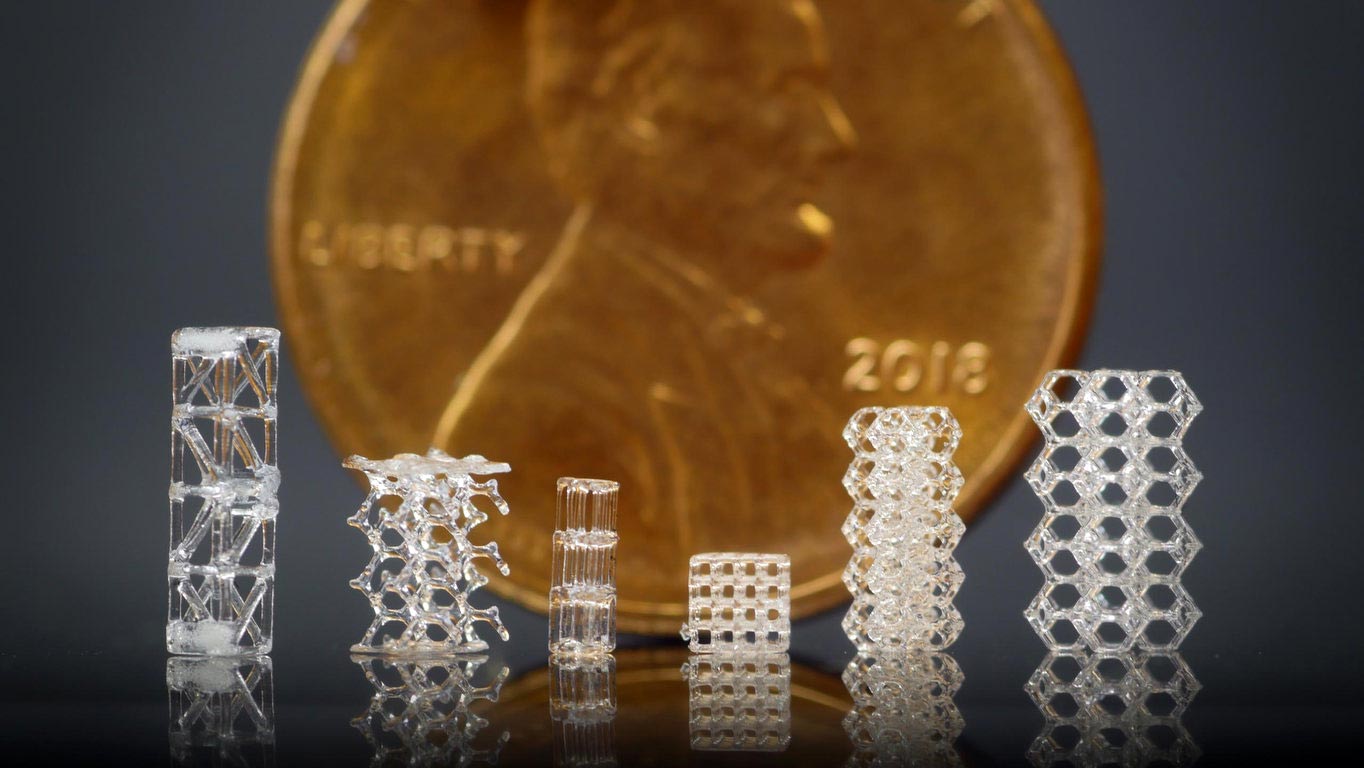

Researchers at UC Berkeley have created a new way to 3D-print glass microstructures, including these 3D printed glass lattices, which are shown in entrance of a U.S. penny for scale. Credit: Photo by Joseph Toombs/UC Berkeley

The production procedure permits quicker production, better optical excellent, and structure overall flexibility.

Scientists at the

A 3D-printed, trifurcated microtubule model. Credit: Video by Adam Lau/Berkeley Engineering

Working with scientists from the Albert Ludwig University of Freiburg in Germany, the researchers extended the capabilities of a 3D-printing process they developed three years ago — computed axial lithography (CAL) — to print much finer features and to print in glass. They dubbed this new system “micro-CAL.”

Glass is often the preferred material for creating complicated microscopic objects, including lenses in compact, high-quality cameras used in smartphones and endoscopes, as well as microfluidic devices used to analyze or process minute amounts of liquid. However, present manufacturing methods can be slow, expensive, and limited in their ability to meet the industry’s increasing demands.

The CAL process is fundamentally different from today’s industrial 3D-printing manufacturing processes, which build up objects from thin layers of material. This technique can be time-intensive and result in rough surface texture. CAL, however, 3D-prints the entire object simultaneously. Researchers use a laser to project patterns of light into a rotating volume of light-sensitive material, building up a 3D light dose that then solidifies in the desired shape. The layer-less nature of the CAL process enables smooth surfaces and complex geometries.

This study pushes the boundaries of CAL to demonstrate its ability to print microscale features in glass structures. “When we first published this method in 2019, CAL could print objects into polymers with features down to about a third of a millimeter in size,” said Hayden Taylor, principal investigator and professor of mechanical engineering at UC Berkeley.

“Now, with micro-CAL, we can print objects in polymers with features down to about 20 millionths of a meter, or about a quarter of a human hair’s breadth. And for the first time, we have shown how this method can print not only into polymers but also into glass, with features down to about 50 millionths of a meter.”

Researchers at UC Berkeley have developed a new way to 3D print intricate glass microstructures, including this tetrakaidecahedron lattice structure. Credit: Photo by Adam Lau/UC Berkeley

To print the glass, Taylor and his research team collaborated with scientists from the Albert Ludwig University of Freiburg, who have developed a special resin material containing nanoparticles of glass surrounded by a light-sensitive binder liquid. Digital light projections from the printer solidify the binder, then the researchers heat the printed object to remove the binder and fuse the particles together into a solid object of pure glass.

“The key enabler here is that the binder has

a refractive index that is virtually identical to that of the glass, so that light passes through the material with virtually no scattering,” said Taylor. “The CAL printing process and this Glassomer [GmbH]-designed product are a fantastic match for each and every other.”

Scanning electron micrograph of cubic lattice with 20 micrometer lattice users. Credit history: Photograph by Joseph Toombs/UC Berkeley

The study team, which bundled lead author Joseph Toombs, a Ph.D. college student in Taylor’s lab, also ran assessments and uncovered that the CAL-printed glass objects experienced far more reliable energy than people made using a standard layer-primarily based printing procedure. “Glass objects are likely to split more conveniently when they have additional flaws or cracks, or have a rough floor,” explained Taylor. “CAL’s ability to make objects with smoother surfaces than other, layer-dependent 3D-printing procedures is consequently a significant opportunity benefit.”

UC Berkeley graduate university student Joseph Toombs works by using tweezers to pick up a glass lattice structure that was created using an revolutionary new 3D-printing system. Credit: Photograph by Adam Lau/UC Berkeley

The CAL 3D-printing method delivers suppliers of microscopic glass objects a new and a lot more productive way to satisfy customers’ demanding prerequisites for geometry, dimensions and optical and mechanical properties. Exclusively, this involves brands of microscopic optical parts, which are a key aspect of compact cameras, virtual reality headsets, superior microscopes and other scientific devices. “Being equipped to make these elements more quickly and with extra geometric freedom could perhaps direct to new device features or lower-value items,” reported Taylor.

Reference: “Volumetric additive manufacturing of silica glass with microscale computed axial lithography” by Joseph T. Toombs, Manuel Luitz, Caitlyn C. Cook, Sophie Jenne, Chi Chung Li, Bastian E. Rapp, Frederik Kotz-Helmer and Hayden K. Taylor, 14 April 2022, Science.

DOI: 10.1126/science.abm6459

This review was funded by the Countrywide Science Basis, the European Research Council, the Carl Zeiss Basis, the German Exploration Foundation and the U.S. Department of Vitality.

[ad_2]

Source hyperlink